Head Loss

The head loss that

occurs in pipes is dependent on the flow velocity, pipe length and diameter,

and a friction factor based on the roughness of the pipe and

the Reynolds

number of the flow. The

head loss that occurs in the components of a flow path can be correlated to a

piping length that would cause an equivalent head loss.

Head Loss

Head loss is a measure of the reduction in the

total head (sum of elevation

head, velocity head and pressure head) of the fluid as it moves through a fluid system. Head loss is

unavoidable in real fluids

It is present because of: the friction between

the fluid and the walls of the pipe; the friction between adjacent fluid

particles as they move relative to one another

and the turbulence caused whenever the flow is

redirected or affected in any way by such components as piping entrances and

exits, pumps, valves, flow reducers, and fittings

Frictional loss is that part of the total head loss that

occurs as the fluid flows through straight pipes

The head loss for

fluid flow is directly proportional to the length of pipe, the square of the

fluid velocity, and a term accounting for fluid friction called the friction

factor. The head loss is inversely proportional to the diameter of the pipe.

Friction Factor

The friction factor

has been determined to depend on the Reynolds

number for the flow and

the degree of roughness of the pipe's inner surface

The quantity used to

measure the roughness of the pipe is called the relative roughness, which

equals the average height of surface irregularities (ε) divided by the pipe diameter (D)

Relative Roughness=εD

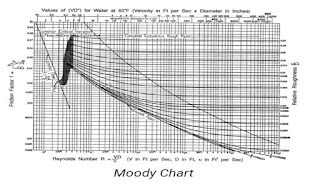

The value of the friction factor is usually obtained from the Moody Chart, an example of which is shown below. The Moody Chart can be used to determine the friction factor based on the Reynolds number and the relative roughness

Example

Determine the friction factor (f) for fluid flow in a pipe

that has a Reynolds number of 40,000 and a relative roughness of 0.01.

Solution

Using the Moody Chart, a Reynolds number of 40,000 intersects

the curve corresponding to a relative roughness of 0.01 at a friction factor of

0.04

Darcy's

Equation

The frictional head

loss can be calculated using a mathematical relationship that is known as

Darcy's equation for head loss. The equation takes two distinct forms. The

first form of Darcy's equation determines the losses in the system associated

with the length of the pipe

where:

|

f |

= |

friction factor

(unitless) |

|

L |

= |

length of pipe (ft) |

|

D |

= |

diameter of pipe

(ft) |

|

v |

= |

fluid velocity

(ft/sec) |

|

g |

= |

gravitational

acceleration (ft/sec2) |

Minor Losses

The losses that occur

in pipelines due to bends, elbows, joints, valves, etc. are sometimes

called minor losses. This is a misnomer because in many cases these

losses are more important than the losses due to pipe friction

considered in the

preceding section. For all minor losses in turbulent

flow, the head loss varies

as the square of the velocity. Thus a convenient method of expressing the minor

losses in flow is by means of a loss coefficient (k).

Values of the loss coefficient (k) for typical situations and fittings is found

in standard handbooks. The form of Darcy's equation used to calculate minor

losses of individual fluid system components is expressed by Equation

ليست هناك تعليقات:

إرسال تعليق